FAQ

A

Allow/Shut compressed air to flow into different paths from one or more sources.A

(1)Check if the operating pressure is too low, or the pilot body piston seal is dusted. (The lowest operating pressure should not less than 1.5 bar.)(2)The wire socket on the valve or the plug went loose, make sure the plug and socket is tightly connect.

(3)Check if the spring has lost it elasticity or it has deformed, both facts could affect the spool fail to return to it original position.

A

Check if the Plunger packing seal is dusted or damaged, replace new packing seal if necessaryA

Check if the piston seal is damaged, replace new seal if necessary.A

Check if the spool or spool seal is damaged, replace new spool or spool seal if necessary. Make sure the piping for P and R port is correctly connected.A

Check if the spool seal is damaged, replace new seal if necessary. Make sure the piping for P and A(B) port is correctly connected.A

The air should be filtered with 5um filter element.A

Lubricant was included/applied during assembly, therefore additional lubrication is not required under normal circumstances.A

Do not use valves in atmospheres of corrosive gases, chemicals, sea water, water vapor.A

Make sure the power is switched off, shut the compressed air and air pressure is completed released from the valve.A

(1) Replace new coil or press the manually override button to check if the solenoid is malfunctioning. (2) Check if the solenoid is burnt. Remove the lead wire and attached it to avometer, if the result shows the circuit is on, then the solenoid is damaged.

A

Make sure the operating pressure is within the pressure range specified in the catalogue. If the operating pressure exceeds the pressure range, suspend all operation to prevent the directional valve explode or air leak.A

IP stands for “International Protection”. It classifies and rates the degree of protection provided against intrusion of dust and water. For example, IP65, The first digit “6” represent “Solid particle protection” level, the second digit “5” represent “Liquid ingress protection” level

A

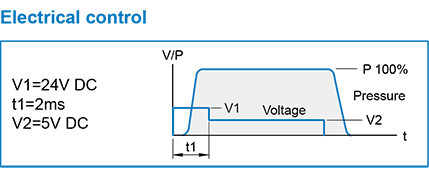

(1) The function of driver is toconvert signal from DC24V(speed-up) to DC5V(hold), the hold voltage will take placein2ms,It's convenient for client to use.

Remark:Max operating freq. up to 250Hz

(2) If the driver is not ordered, the client needs to convert the signal shown in the figure below,in order to ensure the valve functions normally.

Remark:Please follow the electrical control shown in the figure below, in order to avoid the valve burning out.

A

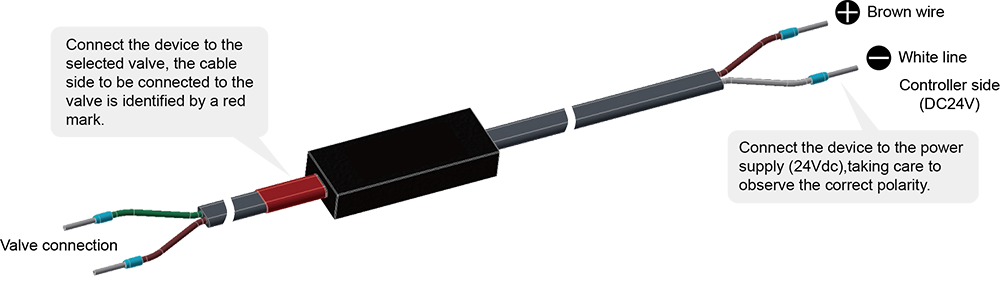

Please follow the connection as shown in the figure below, in order to avoid burnout.